Precision. Performance. Partnership.

Over 20 Years of Precision Rotogravure Cylinder Manufacturing — Trusted by Packaging Leaders and Emerging Brands Alike

At Gugan Roto Graphics, we blend advanced engraving technology with high-quality materials to craft precision rotogravure cylinders for printing and coating. Known for our reliability and fast turnaround, we’re a trusted partner to packaging converters and printing businesses across South India.

Gugan Roto Graphics is a trusted specialist in rotogravure cylinder manufacturing and pre-press solutions, serving over 100+ brands across India. With 19 years of experience and a commitment to uncompromised quality, we help packaging brands achieve sharper, cleaner, and more consistent prints.

Started in 2006 as BDM Creators, we were one of the leading manufacturers of chemical cylinders, known for our quality, consistency, and accuracy. Over the years, we expanded our capabilities, upgraded our technology, and evolved into Gugan Roto Graphics — a complete rotogravure cylinder manufacturing partner trusted across multiple industries.

Every cylinder we produce reflects the perfect blend of craftsmanship, precision engineering, and deep printing knowledge. We have handled 1,000+ SKUs across different industries, ensuring each project meets the highest standards of accuracy, durability, and print consistency.

Our Mission

To deliver reliable, high-precision rotogravure cylinders that empower brands to achieve superior print quality every single time.

Our Vision

To become one of South India’s most trusted partners in packaging excellence through continuous innovation, precision technology, and long-term client relationships.

Our Expertise

From pre-press to finishing, we manage the complete cylinder-making workflow with in-depth precision

In House Cylinder Base Preparation

Every cylinder starts with a perfectly engineered base shell designed, machined, and finished by our own team.

Pre-Press Department

Using Adobe, CorelDRAW, and ArtPro, we prepare every artwork with perfect color, layout accuracy, and print readiness.

Using high-grade copper, we create a smooth and consistent surface on each cylinder.

This helps us achieve better detail, clarity, and stability during engraving

Copper Plating

Polishing

Each cylinder goes through a careful polishing process to ensure uniform finishing.

This step improves the accuracy of engraving and prevents surface deviations.

A smooth, polished base leads to consistent, high-quality printing on press.

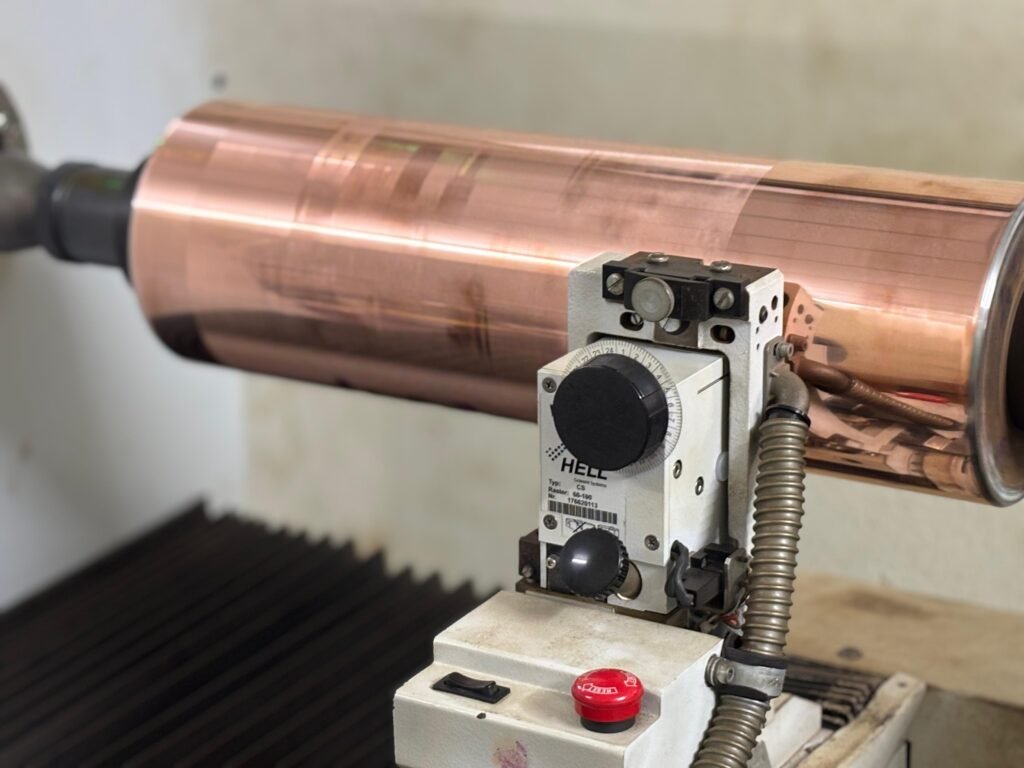

Engraving

We use HELL engraving technology to engrave every cylinder with high precision.

This ensures sharper details, accurate cell depth, and consistent print quality.

Chrome Plating

Every cylinder is chrome plated to increase hardness and prevent wear during printing.

This ensures smoother runs and consistent results across long jobs.

Proofing

We run every cylinder on our proofing machine to produce an actual print sample.

This helps us verify color, engraving accuracy, and print clarity before it reaches your press.

Packing

Every cylinder is protected using our 3-layer packing system to avoid scratches, moisture, and transit damage.

This ensures each cylinder reaches your press safely and remains in perfect, ready-to-use condition.